Chemical Production

In order to maintain the customer satisfaction in the highest level, Marfom uses the best chemical and physical production technologies which provides a production that meets the customer demands such as various densities, sizes, colors, shapes and other physical properties.

Marfom has the capability of producing foams with various densities and different physical properties such as “Hard”, “Standard”, “Soft”, “High-Resilience”, “Viscoelastic” and “Nonflammable”. Marfom has a foam manufacturing machine, that was produced by a German Company, HENNECKE and provides production with high pressure and full automation. Foams, that are produced with this technology, have uniform and stable cell structure.

By means of this technology, it is possible to produce flexible polyurethane foam with desired features ( even the low-density foams) and in accordance with Turkish, Europe, American and English standards.

Physical Production (Cutting)

Block Cutting

Continuous blocks are taken from the wide inventory pool and they are cut with automatic dimensioning machine. After then, the dimensioned blocks are delivered to the customer directly or they are sent to the relevant machines for a secondary cutting operation in accordance with the customer wishes.Vertical & Horizontal Cutting

Foams that have various densities and properties, it is possible to cut the foam into desired thickness with horizontal blade on rotating table.Contour Cutting

Foams that have various densities and properties, are cutting into desired shapes with the computer-controlled CNC machine. This machine have blades that are able to rotate by 180 or 360 degrees within the coordinates that were determined before. Seat and back foams, that are used in Mattress & Furniture Industry, can be cut with this contour cutting technology.Roll Cutting

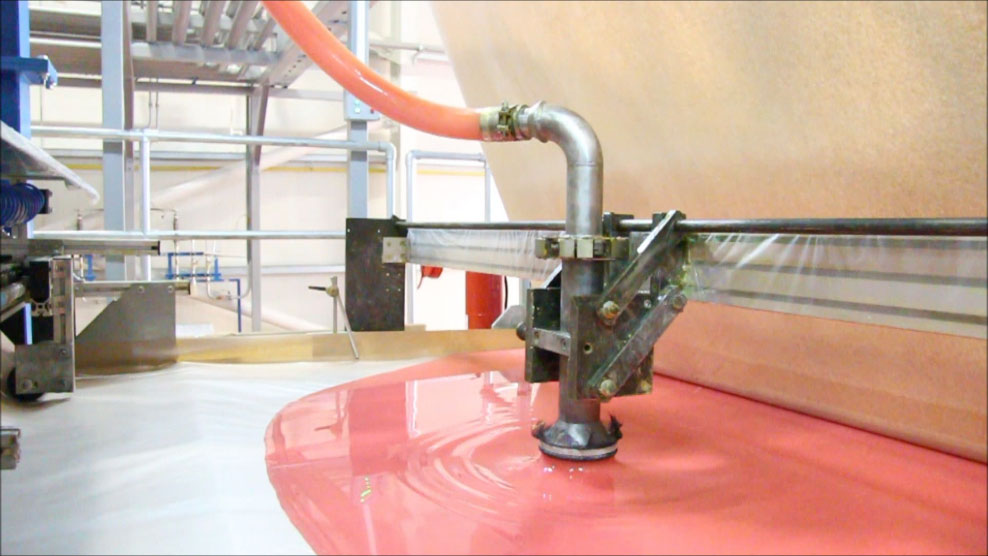

Foams, that are used in Lamination, Mattress & Furniture Industries, are rolled while they are being cut into the thicknesses of 0,3 cm to 5 cm.Packaging

Packaging Machine 1

MARFOM shows sensitivity to presentation of the products as well as manufacturing stages. MARFOM, who made important investments for packaging, packes the products with hi-tech packaging methods and offers advantages to its customers in storage and delivery processes.

In MARFOM, packaging process begins with final quality control operation. After then, unpacked products enters the automatic packaging machine which was designed specially for polyurethane foam packaging. Finally, they exit from machine as packed regularly with polyethylene film.

Packaging Machine 2 (Roll Packaging)

Roll Packaging Machine offers advantages for storage and delivery by reducing the volume of the foam rolls with the help of its compression force. This machine has the capacity and technology of reducing diameter and volume of the rolls in varying proportions (max 50%) depending on the foam density.